STELA Food & Pet Food Drying Systems

Continuous Belt Dryers for Food and Pet Food ApplicationsFood and Pet Food Belt Dryers

Continuous Belt Dryer Systems

Designed for food and pet food applications requiring gentle drying and precise moisture control.

System Type: Continuous Belt Dryer

Drying Method: Low-temperature drying

Design Focus: Gentle handling, hygienic design, scalable capacity

For North American projects, STELA food and pet food belt dryers are exclusively distributed by Nyle Dehydrators.

STELA Food & Pet Food Belt Dryers: Precision Drying by Design

STELA food and pet food belt dryers are engineered around controlled, low-temperature drying to protect sensitive products while delivering stable, repeatable operation. Continuous belt transport, controlled residence time, and modular system design allow drying conditions to be tailored to product characteristics and moisture targets.

Each system is custom engineered to match product behavior, throughput requirements, and operational constraints. Stainless steel construction, hygienic layouts, and gentle product handling support food-grade operation while maintaining long-term reliability in industrial environments.

Typical Food and Pet Food Applications

- Fruits and vegetables

- Herbs and spices

- Snacks, nuts, and cereals

- Ingredients and functional food components

- Pet food, treats, and extrudates

Food & Pet Food Dryer Types

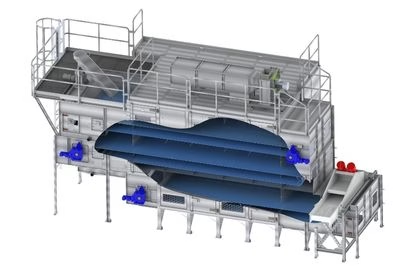

Belt Dryer Type BTF-L

> Layer dryer for products requiring longer retention time

The belt dryer type BTF-L is a layer dryer combining multiple belts stacked vertically within a compact housing. This multi-layer design allows for extended retention time within a reduced footprint, making it well suited for products requiring gradual warming and uniform drying.

This configuration provides an expanded drying surface within a reduced footprint, making it well suited for continuous food and pet food production environments.

Key characteristics

- Continuous belt dryer with multiple belts stacked vertically

- Large drying surface in a compact installation footprint

- Controlled residence time through adjustable belt speed

- Designed for higher throughput continuous operation

Design

- Stainless steel construction for food and pet food processing

- Compact enclosed dryer housing supporting consistent drying conditions

- Designed for uniform drying across larger product volumes

Typical applications

- Food and pet food products with lower moisture removal requirements

- Higher-throughput production environments

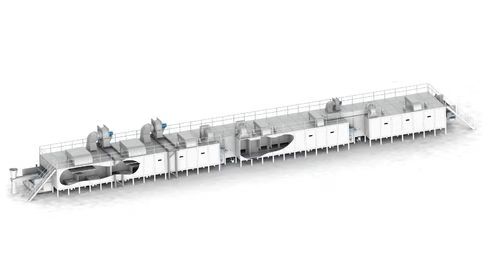

Belt Dryer Type BTF-S

> Optimized for higher throughput with shorter retention times

The belt dryer type BTF-S is an efficient stage dryer, specially designed for use in the food and pet food sectors. Stage dryers are characterized by multiple belts arranged sequentially, one behind the other, allowing the product to pass through successive drying stages.

This staged configuration enables precise control of residence time and airflow, making it well suited for applications requiring shorter retention times and higher throughput in controlled, low-temperature drying.

Key characteristics

- Continuous belt dryer configured as a multi-stage dryer

- Multiple drying stages arranged sequentially

- Controlled residence time via adjustable belt speed

- Low-temperature drying for gentle product treatment

Design

- Stainless steel construction for food-grade applications

- Enclosed system design supporting controlled drying conditions

- Designed for uniform product distribution throughout the drying stages

Typical applications

- Food and pet food products with higher moisture content

- Applications requiring gradual, staged moisture reduction