by STELA Insights | Feb 12, 2026 | Events

STELA Drying Technology will be represented at PACK EXPO East, taking place February 17–19, 2026, at the Pennsylvania Convention Center in Philadelphia. STELA’s Food and Pet Food continuous belt drying solutions will be featured at the booth of Nyle Dehydrators,...

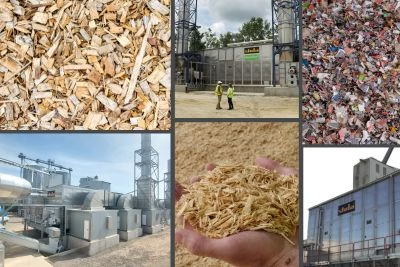

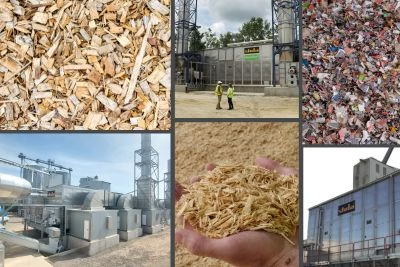

by STELA Insights | Jan 12, 2026 | Biomass Drying Solutions, News, Pellet Drying Technology, Sustainable Drying Techniques, Traditional vs. Belt Drying

Key questions for engineers, consultants, and project planners to ensure the best fit for performance, efficiency, and long-term cost. Selecting the right industrial dryer is one of the most important decisions in many production, processing, or renewable fuel...

by STELA Insights | Sep 15, 2025 | Case Study, Case Study Biochar

A fast-track drying solution that helped a Maine biochar start-up stay on schedule Challenge: Standard Biocarbon (SBC), a biochar start-up in Enfield, Maine, faced an urgent challenge. The company’s project timeline was delayed, and the dry feedstock originally...

by STELA Insights | Aug 21, 2025 | Events

STELA Laxhuber GmbH is pleased to announce our participation at WEFTEC 2025, the 98th Annual WEF Technical Exhibition & Conference, taking place at McCormick Place in Chicago, Illinois. We will be exhibiting as part of the Bavarian Pavilion, organized by Bayern...

by STELA Insights | Aug 21, 2025 | Events

STELA Drying Technology is proud to be a Silver Sponsor of the 2025 APA–EWTA Annual Meeting, taking place October 4–7, 2025, at the Sheraton Grand at Wild Horse Pass in Phoenix, Arizona. With increasing pressure to reduce emissions and optimize production, STELA’s...